Opis

Funkcje kruszarki do skał ciągnikowych do rekultywacji rolniczej

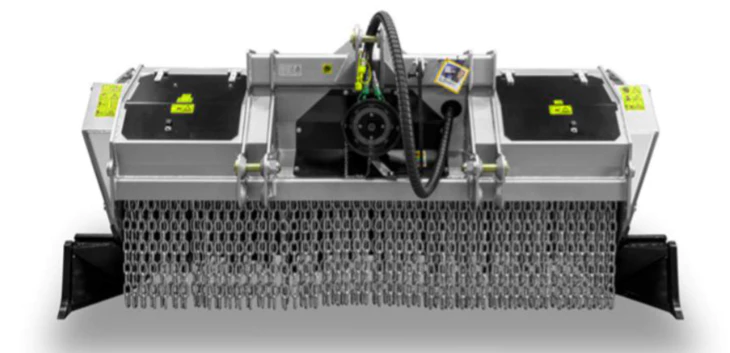

Kruszarki do kamieni do ciągników o mocy 80–280 KM. Szeroki otwór na materiały umożliwia profesjonalistom kruszenie kamieni o średnicy do 30 cm i pracę na głębokości do 20 cm.

Głębokość robocza: maks. 20 cm

Średnica rozdrabniania: Ø 30 cm max

Ciągnik: od 80 do 280 KM

- Spódnica z płytą bazową odporną na zużycie Hardox i wymiennymi lemieszami pługa

- Umożliwia lepszą penetrację gruntu

- Hydrauliczna osłona tylna

- Skutecznie kontroluje wielkość cząstek przetwarzanych materiałów

- Bardzo duży otwór

- Umożliwia przedostanie się skał powierzchniowych do komory kruszącej

- Mocowana śrubami, wymienna, odporna na zużycie warstwa ochronna Hardox

- Łatwy w utrzymaniu, odpowiedni do ciężkich prac

Dane techniczne

| Specyfikacja | AM 125 | AM 150 | AM 175 | AM 200 | AM 225 | AM 200 | AM 225 |

| Moc – KM | 80 – 110 | 150 – 220 | 160 – 220 | 170 – 220 | 180 – 220 | 200 – 280 | 200 – 280 |

| WOM – obr./min | 540 lub 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Szerokość robocza – mm (cale) | 1340 (53) | 1584 (62) | 1824 (72) | 2064 (81) | 2304 (91) | 2064 (81) | 2304 (91) |

| Całkowita szerokość – mm (cale) | 1760 (69) | 2020 (80) | 2260 (89) | 2500 (98) | 2740 (108) | 2500 (98) | 2740 (108) |

| Maksymalna średnica rozdrabniania (kamieni) – mm (cale) | 300 (12) | 300 (12) | 300 (12) | 300 (12) | 300 (12) | 300 (12) | 300 (12) |

| Maksymalna głębokość robocza – mm (cale) | 200 (8) | 200 (8) | 200 (8) | 200 (8) | 200 (8) | 200 (8) | 200 (8) |

| Waga – kg (funty) | 1850 (4079) | 3000 (6614) | 3250 (7165) | 3550 (7826) | 3800 (8378) | 3600 (7937) | 3840 (8466) |

| Średnica wirnika – mm (cale) | 550 (21.7) | 550 (21.7) | 550 (21.7) | 550 (21.7) | 550 (21.7) | 550 (21.7) | 550 (21.7) |

| Ilość zębów – AM/3 + AM/3/HD | 26 + 4 | 32 + 4 | 38 + 4 | 42 + 4 | 48 + 4 | 42 + 4 | 48 + 4 |

Zalety kruszarki do skał ciągnikowej w rekultywacji rolniczej

- Wydajne usuwanie kamieni: Kruszarki do kamieni montowane na ciągnikach z łatwością rozbijają duże skały na powierzchni i pod ziemią, redukując konieczność ręcznej pracy i zwiększając szybkość oczyszczania terenu.

- Poprawa tekstury i produktywności gleby: Rozbijając skały i włączając je do gleby, maszyna poprawia penetrację korzeni, retencję wody i ogólną kondycję gleby, co przekłada się na poprawę warunków glebowych na odzyskanych gruntach rolnych.

- Mniejsze zużycie sprzętu: rozbijanie kamieni przed orką lub siewem chroni traktory i narzędzia przed uszkodzeniami, wydłużając ich żywotność i zmniejszając koszty napraw.

- Dostosowanie do różnych terenów: Zaprojektowane do trudnego terenu i rekultywacji niewykorzystanych gruntów rolnych, w tym obszarów skalistych, przekształcania pastwisk i przekształcania ugorów.

- Ekonomiczna rekultywacja gruntów: Maszyna pozwala na obniżenie kosztów projektu i przyspieszenie siewu dzięki szybszemu oczyszczaniu i mniejszej konieczności ręcznego usuwania.

Zasada działania kruszarki do skał ciągnikowej

Montaż i podłączenie zasilania: Kruszarka do kamieni jest montowana na trzypunktowym zawieszeniu ciągnika lub podłączona za pomocą wytrzymałego układu zawieszenia i napędzana wałkiem odbioru mocy (WOM).

Działanie wirnika i komory kruszenia: Moc z ciągnika jest przenoszona na wirnik, który jest wyposażony w hartowane ostrza kruszące i płyty reakcyjne. Obracający się wirnik uderza w skały i kamienie, rozbijając je na mniejsze fragmenty.

Regulacja głębokości i szerokości: Operator może ustawić szerokość i głębokość roboczą za pomocą sterowania hydraulicznego lub regulacji mechanicznej, aby dostosować ją do rozmiaru kamieni i warunków glebowych. Typowa głębokość robocza wynosi 10–20 cm, w zależności od modelu.

Separacja kamieni i mieszanie gleby: Pokruszone kamienie są mieszane z luźną glebą, tworząc bardziej odpowiednie podłoże pod siew. Mniejsze kamienie pozostają na polu, a większe można zebrać lub rozrzucić.

Ostateczne niwelowanie: Z tyłu maszyny można zamontować listwę wyrównującą lub grabie, aby wyrównać teren i przygotować go do późniejszego sadzenia roślin lub budowy infrastruktury.

Kruszarka do kamieni ciągnikowych do winnic Standardowe wyposażenie

- Przekładnia jednokierunkowa

- Napęd pasowy trapezowy (oprócz STCM-125)

- Napęd pasowy (STCM-125)

- Centralny wałek odbioru mocy ze sprzęgłem krzywkowym

- Podparcie wału odbioru mocy w stanie stacjonarnym

- Regulowana koparka

- Zamknięta obudowa pyłoszczelna (z wyjątkiem STCM-125)

- Wymienne, odporne na zużycie płyty stalowe (oprócz STCM-125)

- Regulowana hydrauliczna koparka (oprócz STCM-125)

- Wymienne łańcuchy ochronne (STCM-125)

- Przykręcane wymienne łańcuchy osłonowe (z wyjątkiem STCM-125)

- Koparka spawana płasko (z wyjątkiem STCM-125)

- Wymienny wał wirnika ze stali kutej

- Wirnik zębaty STC/3

- Odporna na zużycie, wymienna płyta podłogowa

- Odporne na zużycie płyty boczne

- Regulowana płoza

- Przelotowy płoz

- Hydrauliczna osłona tylna

Opinie klientów

„Użyliśmy tej kruszarki zamontowanej na traktorze, aby oczyścić kamieniste pole w południowej Hiszpanii. W ciągu dwóch tygodni rozdrobniła ona setki ton skał, wyrównując teren pod bezpośredni zasiew. Uszkodzenia spowodowane przez traktor zmniejszyły się, a wydajność wzrosła”.

— Klient: Wykonawca rekultywacji gruntów, Andaluzja, Hiszpania

„W naszym gospodarstwie w środkowych Włoszech ta maszyna z łatwością radziła sobie z nierównym, wapiennym terenem. Struktura gleby uległa poprawie, a nowo zasadzone rośliny lepiej się ukorzeniały. Obsługa klienta była responsywna, a części docierały szybko.”

— Klient: Rolnik, Toskania, Włochy

„Kupiliśmy tę kruszarkę do kamieni, aby odnowić stare pastwisko w Brazylii. Maszyna ta może rozłupywać skały powierzchniowe i podziemne, mieszając je z glebą, tworząc równe pastwisko nadające się do wypasu i produkcji paszy. Rezultaty są znakomite.”

— Klient: Wykonawca usług rolniczych, São Paulo, Brazylia

Przegląd firmy i certyfikaty

My, Italy Watanabe Agricultural Stone Crusher Co., Ltd., mamy ponad 15-letnie doświadczenie. Nasza fabryka integruje badania i rozwój, produkcję, kontrolę jakości, obróbkę skrawaniem, montaż i globalne usługi dostawcze, gwarantując stabilną wydajność produktów i doskonałą obsługę klienta.

Stosujemy rygorystyczne procesy zarządzania jakością, posiadamy profesjonalny zespół inżynierów, zaawansowany sprzęt produkcyjny i stawiamy na dostarczanie trwałych maszyn spełniających międzynarodowe standardy.

Nasza fabryka posiada wszystkie niezbędne certyfikaty wymagane przy produkcji maszyn rolniczych, takie jak:

- Certyfikat Systemu Zarządzania Jakością ISO 9001

- Certyfikat bezpieczeństwa maszyn CE (UE)

- Normy emisji spalin EPA/Euro V (dotyczą wyposażonego silnika)

- Certyfikacja spawania i badań wytrzymałości konstrukcji

Posiadamy również nowoczesne zaplecze produkcyjne wyposażone w:

- Centra obróbcze CNC

- Maszyny do cięcia laserowego

- Systemy spawania robotowego

- Sprzęt do dynamicznego wyważania wirników

- Platformy do testowania trwałości i warunków terenowych

Dzięki temu możemy zagwarantować, że każdy produkt sprzedawany na całym świecie jest precyzyjnie wyprodukowany i niezawodny.

Współpracujemy z wieloma partnerami w Europie, Ameryce Północnej i Południowej oraz Azji Południowo-Wschodniej i nieustannie rozszerzamy naszą globalną sieć.

Serwis posprzedażowy i gwarancja

- Standardowa dwuletnia gwarancja producenta obejmująca ramę, skrzynię biegów i wirnik.

- Wystarczająca ilość części zamiennych i globalne wsparcie logistyczne, obejmujące sieć serwisową we Włoszech.

- Zapewniamy wskazówki dotyczące zakładania winnicy i szkolenia dotyczące jej obsługi.

- Aby maksymalnie wydłużyć żywotność sprzętu, realizowany jest program konserwacji zapobiegawczej (miesięczne kontrole, kontrola zużycia wirnika i smarowanie).

- Gwarantuje to długoterminową niezawodność sprzętu i zwiększa Państwa zaufanie do naszego sprzętu.

Często zadawane pytania

P1: Jaki rozmiar ciągnika jest potrzebny do kruszarki do skał?

A: Zależy to od modelu i zastosowania, ale zazwyczaj do większości osprzętów do kruszarek kamieni stosowanych w rekultywacji gruntów nadają się traktory o mocy od 80 do 280 KM.

P2: Czy ta maszyna może pracować w ekstremalnie nierównym lub kamienistym terenie?

Odp.: Tak. Kruszarka ciągnikowa jest przeznaczona do rozdrabniania ciężkich skał, w tym dużych kamieni powierzchniowych i kamieni głęboko osadzonych, dzięki zastosowaniu wzmocnionych wirników i regulowanych ustawień głębokości.

P3: Jak głęboko kruszarka do skał może wniknąć w glebę?

A: Typowa głębokość robocza do 20 cm, w zależności od mocy ciągnika, warunków glebowych i wielkości kamieni. W przypadku bardzo twardego gruntu, mniejsza głębokość może być skuteczniejsza.

P4: Czy ten sprzęt jest kompatybilny z rynkami międzynarodowymi i oferuje wsparcie serwisowe?

O: Tak. Dostarczamy na rynki globalne i zapewniamy pełne wsparcie posprzedażowe, w tym części zamienne, doradztwo techniczne i kontakt serwisowy w głównych regionach.

P5: Jakie są wymagania konserwacyjne kruszarki do skał?

A: Regularna konserwacja obejmuje kontrolę końcówek wirnika, sprawdzanie śrub i płyt ciernych, smarowanie łożysk oraz weryfikację naciągu paska/łańcucha co 100–200 godzin pracy. Planowa konserwacja zapewnia długowieczność i optymalną wydajność.